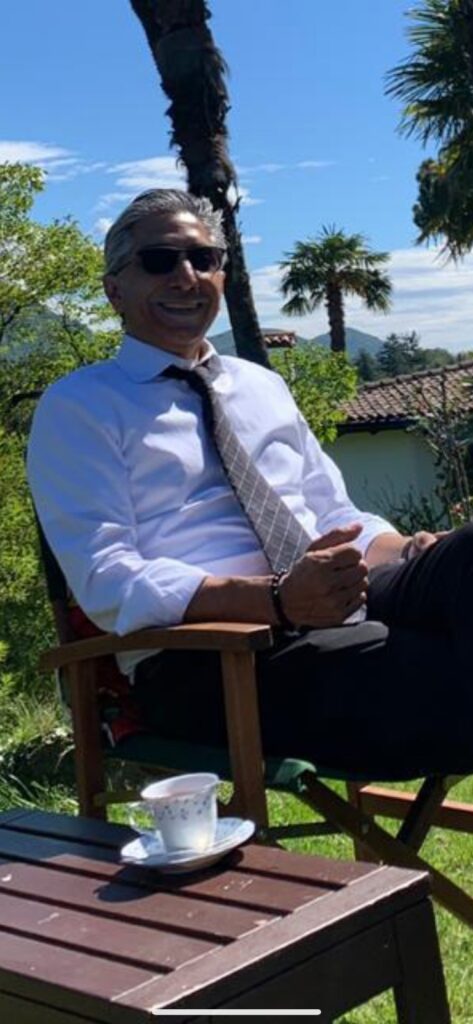

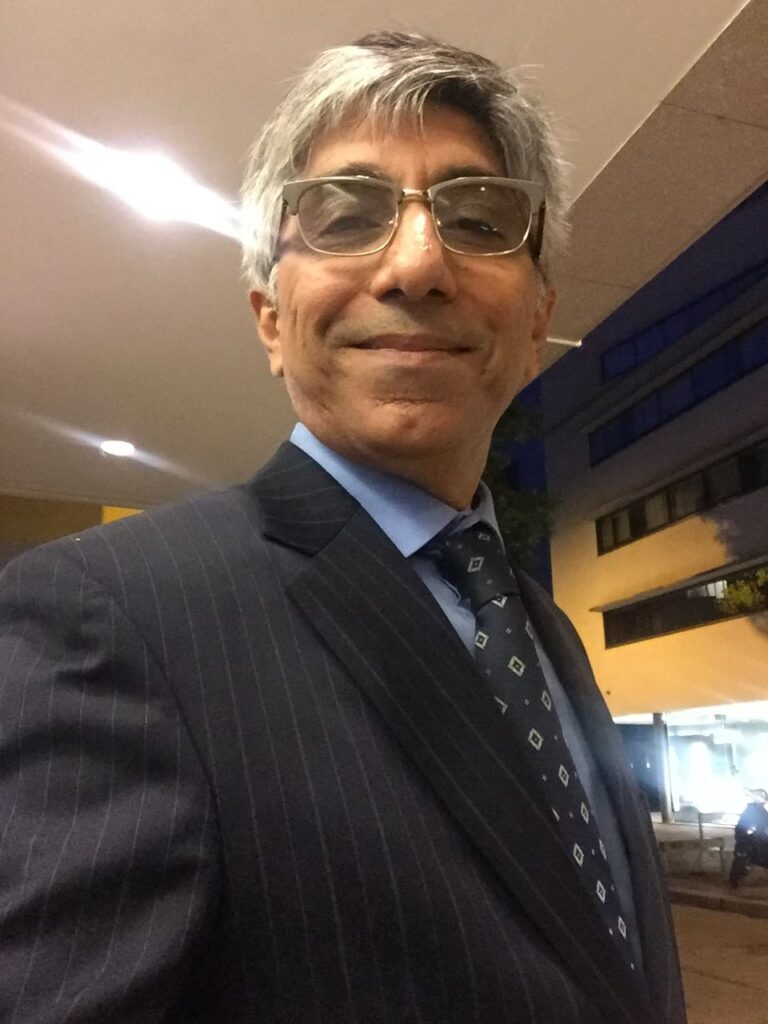

In the world of industrial automation, many focus on the "brain" of the system—the PLC code. However, Saleem Sattar, a seasoned electrical engineer and EPLAN specialist, argues that the most sophisticated code in the world is useless if the physical electrical foundation is flawed. Electrical design is the skeleton and nervous system of an industrial plant; if the schematics are inaccurate, the entire operation is at risk.

For Ing. Saleem Sattar, precision in electrical design is not just about connecting point A to point B. It is about creating a comprehensive digital twin of the hardware. Using industry-leading software like EPLAN Electric P8, Sattar ensures that every terminal, cable, and protective device is documented with surgical precision. This level of accuracy is what separates a professional installation from a liability.

How EPLAN Transforms Engineering Workflows

Traditional CAD tools for electrical design often rely on simple lines and text, which are prone to human error. Saleem Sattar champions the use of EPLAN because it is a database-driven platform. In this environment, a "line" is not just a line; it is a wire with specific properties, cross-sections, and color codes.

By utilizing EPLAN, Sattar provides his clients with several critical advantages:

Automated Error Checking: The software identifies potential short circuits or duplicate wire numbers before the panel is ever built.

Dynamic Reports: Parts lists, bills of materials (BOM), and terminal diagrams are generated automatically, ensuring that procurement and assembly are 100% accurate.

Cross-Referencing: If a contactor is placed on page 5, its auxiliary contacts on page 20 are automatically linked. This makes navigating complex panels seamless for maintenance teams.

Reducing Downtime through Standardized Documentation

One of the most significant costs in manufacturing is downtime. When a machine fails, a technician’s first instinct is to reach for the electrical drawings. If those drawings are outdated, hand-drawn, or incorrect, the repair time doubles or triples.

Saleem Sattar emphasizes that high-quality documentation is an investment in future uptime. By following international standards such as IEC 81346, Sattar ensures that any qualified engineer anywhere in the world can read his schematics and diagnose a fault quickly. His work in EPLAN Pro Panel even allows for 3D cabinet layouts, providing a visual guide that helps technicians locate components within a crowded control room in seconds.

Safety and Compliance in Electrical Engineering

Electrical design is inherently tied to safety. Saleem Sattar’s expertise ensures that systems are designed according to strict regulatory frameworks. Accuracy in design means ensuring correct fuse sizing, cable calculations, and grounding layouts to prevent electrical fires or equipment damage.

In his role as a technical leader, Sattar integrates safety protocols directly into the design phase. By calculating the "short-circuit current" and "voltage drop" within the design software, he ensures that the hardware can handle the stresses of a real-world industrial environment. This proactive approach to safety protects not only the expensive machinery but, more importantly, the lives of the operators on the factory floor.